Dilute & Concentrated

All Specific Gravities: 1.150-1.180 - 1.200-1.220 - 1.250-1.300-1.400-1.800

It has been observed with Major Battery Manufacturing Units over the last few years that they are facing huge setbacks due to Self-Dilution from Concentrated Sulphuric Acid at their factory and gradually look to switch over to procure Dilute Sulphuric Acid directly.

Buying Concentrated Sulphuric Acid of 1.840 sp gr & diluting in battery factory incurs a lot of hidden costs & quality issues which a battery company realizes in the long term. It is much advantageous in the long run in terms of cost saving and quality assurance to buy Dilute Acid of required gravity like 1.200 or 1.220 directly.

1)Today with increase in volumes of batteries manufactured by a Company owing to the huge demand, it is also imperative to maintain quality of battery, reduce battery rejections & claims.

2)Sulphuric Acid Electrolyte cost works out to just less than 1% of the entire battery’s cost. No major cost reduction can be achieved through acid considering overall battery cost. However its Quality is very crucial in the performance of the battery.

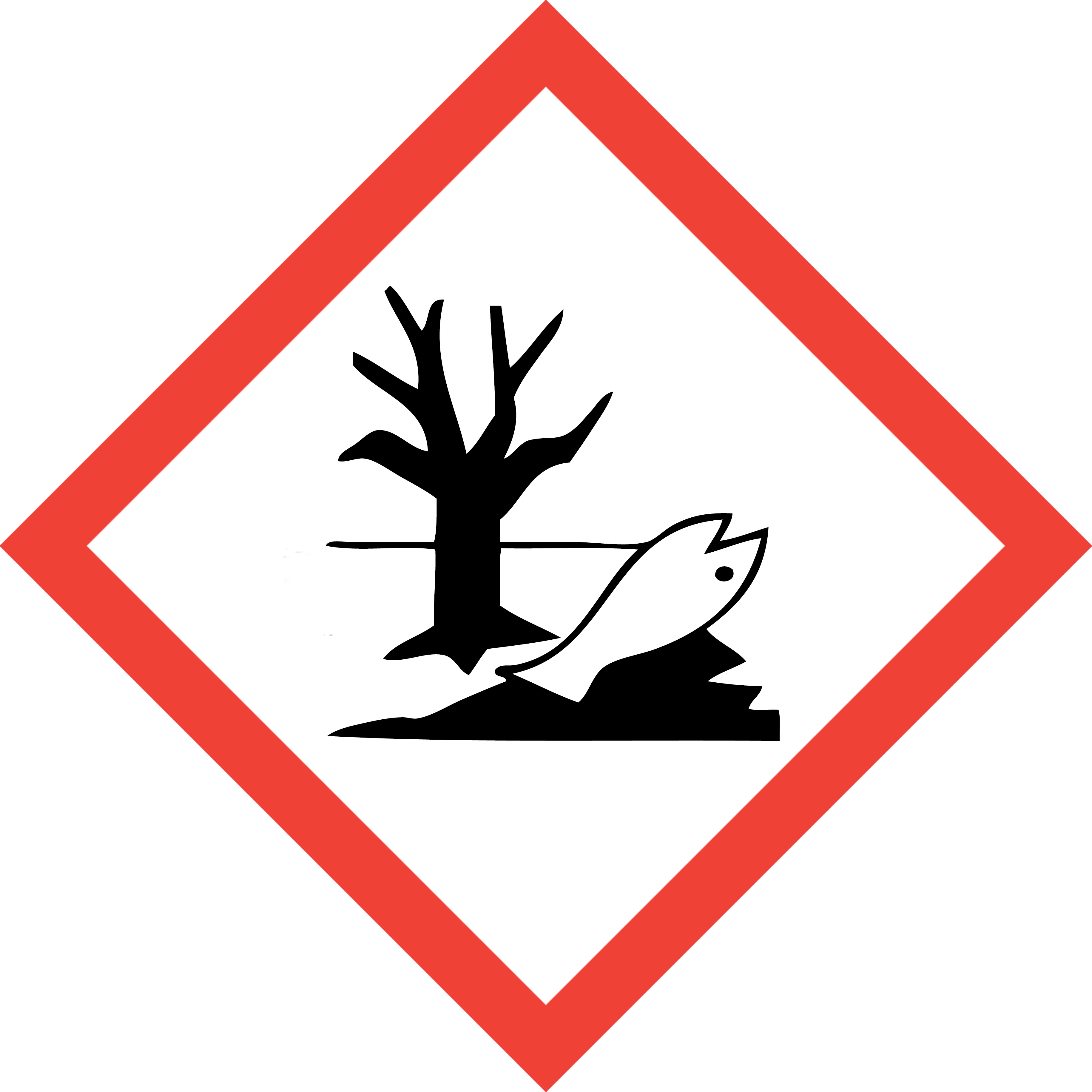

3)It is very Dangerous to store 98% Concentrated Sulphuric Acid as it involves a lot of Risk.

4)In a battery plant, Concentrated Sulphuric Dilution is a difficult task and involves a lot of Quality and handling issues.

5)It is more practical to procure Dilute Sulphuric Acid directly and ensure Quality as well as eliminate your difficulties faced in acid handling which comprises of less than 1% of your battery cost.

6)Instead of Buying Concentrated Sulphuric Acid of 1.84 sp. gr., a company involved in operations of Battery manufacturing should procure Ready to use Dilute Acid of 1.200 or 1.220.

7)Else, buy Acid of 1.400 sp. gr. (52% concentration approx.) & further dilute it as it is relatively much easy & faster to further dilute 1.400 sp gr acid to lower gravities than diluting concentrated acid as there is less exothermic heat evolved, less corrosion, other hazards, cooling time, etc & better quality is obtained. Lower specific gravities like 1.180, 1.200, 1220, 1.240, 1.300 sp.gr. are much easier, faster & hassle free to obtain from 1.400 sp. gr. than from 1.840 sp. gr.

Considering all these above factors, it is highly recommended to purchase dilute Sulphuric Acid & not procure and store Concentrated Sulphuric Acid of 98%.

Following advantages of directly procuring Dilute Acid over Concentrated Acid:

| Parameter | Concentrated Sulphuric Acid | Dilute Sulphuric Acid 1.400 sp. gr. |

|---|---|---|

STABLE IRON & CHLORINE CONTENT |

A Practical Problem faced by many Battery Manufacturing Companies is that the Iron & Chlorine ppm levels in Sulphuric Acid INCREASE with prolonged storage of 98% Sulphuric Acid. | Dilute Sulphuric Acid of lower gravity is in a much stable form. The risk of Increase in Iron & Chlorine content during storage is reduced in dilute acid. |

STABLE QUALITY |

Concentrated Sulphuric Acid being strong in concentration has the affinity to absorb color, increase in its impurity content (by absorbing Iron, Chlorine & others) and also at times turn dark reddish/black. This changing in color and impurity content is very common in concentrated acid which as a practice you do not Quality check once the material gets unloaded at your factory and thereby it gets unfit for use in batteries. |

Dilute Sulphuric Acid minimizes this and it remains stable for a much longer time during storage and handling. |

INCREASE IN IMPURITY CONTENT |

If observed well, there is a formation of thick sludge at the bottom of the storage tank of 98% Concentrated Sulphuric Acid over a period of time. This is due to the settling of free floating particles of Sulphur and other impurities. One cannot imagine these small undissolved particles of Sulphur entering your battery and forming a layer on the plates or at the bottom.

It is very tough to clean storage tanks of Concentrated Acid. Also Concentrated Sulphuric Acid has high affinity towards water as it is hygroscopic in nature. It tends to absorb the moisture in its surrounding and also thereby absorb the impurities present. |

Dilute Acid is comparatively free from this free floating Sulphur & other floating impurities.

It is also easier to clean tanks of Dilute Acid periodically. Dilute Sulphuric Acid minimizes the increase in impurities as it comparatively absorbs minimal moisture and impurities from its surroundings. |

CONSISTENT SPECIFIC GRAVITY |

Concentrated Sulphuric Acid and water have a big difference (double) in their density and therefore it is difficult to blend both of them perfectly.

Further when a company dilutes them together, it is practically observed that the specific gravities are different at different levels in storage tanks. e.g. density can be 1.220 at the bottom of the tank, 1.210 in the mid of the tank & 1.200 at the top of the tank. Further, this difference in specific gravity increases with storage time as heavier acid will tend to settle down and lighter water will tend to rise at the top. Imagine the same Acid of inconsistent specific gravity going into your battery and how it can reversely hamper the performance |

A perfectly Pre blended dilute acid will ensure uniform specific gravity and will not disintegrate easily, maintaining the same specific gravity even after days of storage. |

LESSER EVAPORATION LOSSES |

Dilution of 1.840 sp. gr Acid is a highly exothermic process releasing large quantities of heat energy. When water is added directly to Concentrated acid of 1.840 sp. gr., it forms a boiling mixture and large amount of acid fumes are formed which is nothing but the evaporated Acid. Practically around 12-16% of acid is evaporated in dilution process of 98% Concentrated acid. These losses are difficult to account for. |

Further Dilution from 1.400 sp. gr. Sulphuric Acid is relatively very easier and comparatively produces very low Heat and fumes. It thus minimizes the evaporation losses to almost 25% compared to that of 1.800 sp. gr.

Procuring ready to use Dilute Acid 1.200 sp. gr eliminates these evaporation losses. |

Safety of Handling |

Handling of Concentrated Sulphuric Acid 98 % (1.800 sp.gr.) is a very dangerous & risky job due to its hazardous nature which can lead to grave accidents. | Dilute Acid is relatively much safer to handle |

Life of Dilution Machinery, tanks, etc |

98% Concentrated Acid is heavier to store and also its dilution has high thermal shocks thereby decreasing the life of dilution machinery, tanks, pipes, pumps, etc. | Dilute Sulphuric Acid is comparatively lighter and minimizes thermal shocks and thereby has a minimal negative effect on the life of dilution machinery, tanks, etc. |

Maintenance & wear & tear of machines |

Concentrated Sulphuric Acid tanks, Dilution machinery has a high down time as well as high Maintenance cost | Dilute 1.400 Sulphuric Acid storage and further dilution has minimal Down-time and maintenance. |

Cooling Time & Dilution time |

The Dilution of Concentrated Acid takes a long time cycle to get diluted perfectly and cool down | Further Dilution of Dilute Acid 1.400 sp. gr. acid is just 20% than that of Dilution of Concentrated acid with minimized heat. |

Energy Cost |

Concentrated Sulphuric Acid dilution needs more mixing and cooling process, thereby increasing energy cost | Further Dilution of 1.400 Dilute acid may not even need cooling or minimal cooling and easy mixing thereby reducing Energy cost. |

Therefore, it is strongly advised to procure and use DILUTE SULPHURIC ACID directly instead of Concentrated Sulphuric Acid of 1.840 sp. gr.

There is no wealth like knowledge, and no poverty like ignorance.

Sulphuric acid has been classified in four grades depending upon presence of impurity levels:

a) Technical (Tech)

b) Chemically pure (CP)

c) Analytical reagent (AR) or Laboratory Grade (LR)

D) Battery Grade (bg)

Concentration of Sulphuric Acid is directly proportional to its specific gravity. Some of the Concentration and specific gravities of Sulphuric acid are mentioned below :

% of H2SO4 |

Specific Gravity |

|---|---|

30% |

1.260 |

40% |

1.350 |

50% |

1.400 |

98% |

1.840 |

Sulphuric Acid fumes are highly dangerous. They corrode and damage every substance, metal, electrical wires, etc. that they come in contact with. If accidently inhaled, they cause immflamation, severe burns and damage to the eyes, lungs and respiratory track, leading to health hazards. 98% Sulphuric Acid is more prone to emit fumes on a continual basis and hence proves to be a silent killer.

Sulphuric Acid and its fumes (gases) being of a highly corrosive nature, over a period of time corrodes every material in contact with it & around it like metals, its dilution machinery, pumps, pipes, electrical fittings, the factory shed, human health, etc. These losses are difficult to account for.

If sulfuric acid makes direct contact with the eyes, it can cause permanent blindness. If ingested, this chemical may cause internal burns, irreversible organ damage, and possibly death. Exposure to sulfuric acid aerosols at high concentrations leads to severe eye and respiratory tract irritation and tissue damage.

Sulphuric acid is Not flammable but highly reactive. It reacts violently with water with evolution of heat. It also react with organic materials explosively. This chemical is unique because it not only causes chemical burns, but also secondary thermal burns as a result of dehydration.

Sulphuric acid can harm crops and trees, textiles, building materials, animals, and people either as a result of exposure to long-term low concentrations or short-term high concentrations.

.png)

If in eyes:

Immediately flush eyes and skin with copious amounts of water for at least 15 to 30 minutes, holding lids apart to ensure flushing of the entire surface. Do NOT allow victim to rub eyes or keep eyes closed.

If inhaled:

Get medical aid immediately remove patient from exposure to fresh air. Administer approved oxygen supply if breathing is difficult. Administer the artificial respiration or CPR if breathing has ceased. Do NOT use mouth-to-mouth resuscitation.

.png)

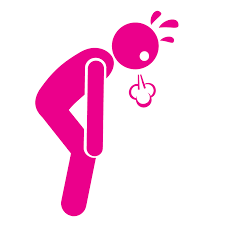

If swallowed:

Do NOT induce vomiting. If victim is conscious and alert, give 2-4 cupfuls of milk or water. If spontaneous vomiting occurs, have victim lean forward with head down to avoid breathing in of vomitus. Never give anything by mouth to an unconscious person. IMMEDIATELY transport victim to an emergency facility.

.png)

Skin/clothes:

Get medical aid immediately. Immediately flush skin with copious quantities of soap and water for at least 15 minutes while removing contaminated clothing and shoes. Wash clothing before reuse. Destroy contaminated shoes.

Handling:

Avoid generating vapour or mists. Immediately report leaks, spills or failures of the safety equipment (e.g. ventilation system). Prevent accidental contact with incompatible chemicals. Never add water to a corrosive. Always add corrosives slowly to COLD water. If product is transferred to another container, ensure new container is suitable for the product. Never reuse empty containers, even if they appear to be clean.

Storage:

Store in an area that is cool, dry, out of direct sunlight and away from heat and ignition sources, separate from incompatible materials. Avoid bulk storage indoors. Regularly inspect for physical changes or signs of crystallization, damage or leaks.

This is unwise and could cost you irreparable damage to your business.

Diluting sulphuric acid should not be taken lightly. It is no cake walk. Sulphuric acid Dilution presents serious challenges that you need to be fully prepared to handle:

Avoid mixing or cutting chemicals in open containers or normal water tanks.

Sulfuric acid can cause serious burns on the skin—even more serious than other acids.

Sulphuric Acid Fumes are silent Killers and cause irrepairable damage to surrounding area as well as serious health hazards to personnel. Thereby use of Compressed air for Dilution to create air mixing by bubbles can be very dangerous and should be avoided.

Use proper protective equipment while diluting acid. Avoid formation of Acid fumes.

Always add acid to water and never water to acid.

TAs the acid get colder it contracts and the apparent density increases and as it gets hot it expands and the apparent density decreases. Major problems occur at temperature extremes. Therefore, When taking specific gravity measurements, it is important to correct for temperature to get a true reading. As a rule of thumb, specific gravity will change by 0.007 points per 1ºC.

No. HCL or Nitric Acid should never be added to a Lead Acid Battery.

The lead-acid battery with sulfuric acid just undergoes reactions involving the lead and gives contained, nonvolatile products. By way of contrast, hydrochloric acid could be oxidized to chlorine gas at the anode and nitric acid could be reduced to nasty nitrogen oxides at the cathode. Such fumes coming from car batteries, will create damage first to the battery plates and then to the surrounding.

Using Normal water to Dilute Sulphuric Acid will hamper the performance of the battery.

This is because the Normal water will contain undesired ions and minerals like Chlorine, iron, etc which will react, thereby reducing the life of a battery.

Also, they will block the pores of the separator reducing the efficiency.

Acids can be neutralized with bases (such as sodium hydroxide, potassium hydroxide) or very basic salts (sodium carbonate, sodium bicarbonate, etc).

Battery acid used for lead acid batteries is dilute sulphuric acid & there are various situations:

1.Yes you can mix old and new acid IF you are putting tested battery grade acid received from a vendor in a storage tank which already contains battery grade acid of good quality. This happens frequently in a battery plant when acid is ordered and replenished as and when the stock diminishes.

2.Yes you can mix old and new acid IF you are replenishing new battery grade acid in a battery containing old battery grade acid. Such situations rarely crop up and are situations wherein the battery has overturned or tilted and lost acid by spilling.

3.No you cannot mix old battery acid from a scrap battery with new battery grade acid of good quality for use as fresh acid. As and when a battery becomes old the acid quality degrades with impurities leaching out from the battery plates as well as separators. In most of the cases the old drained acid when tested has been found to contain metallic impurities or other contaminants which may have got into the battery at the time of topping up with water during the service life.

Copyright © 2016 Kankariya Group. All Rights Reserved.